SmartDFE Home

What is SmartDFE?

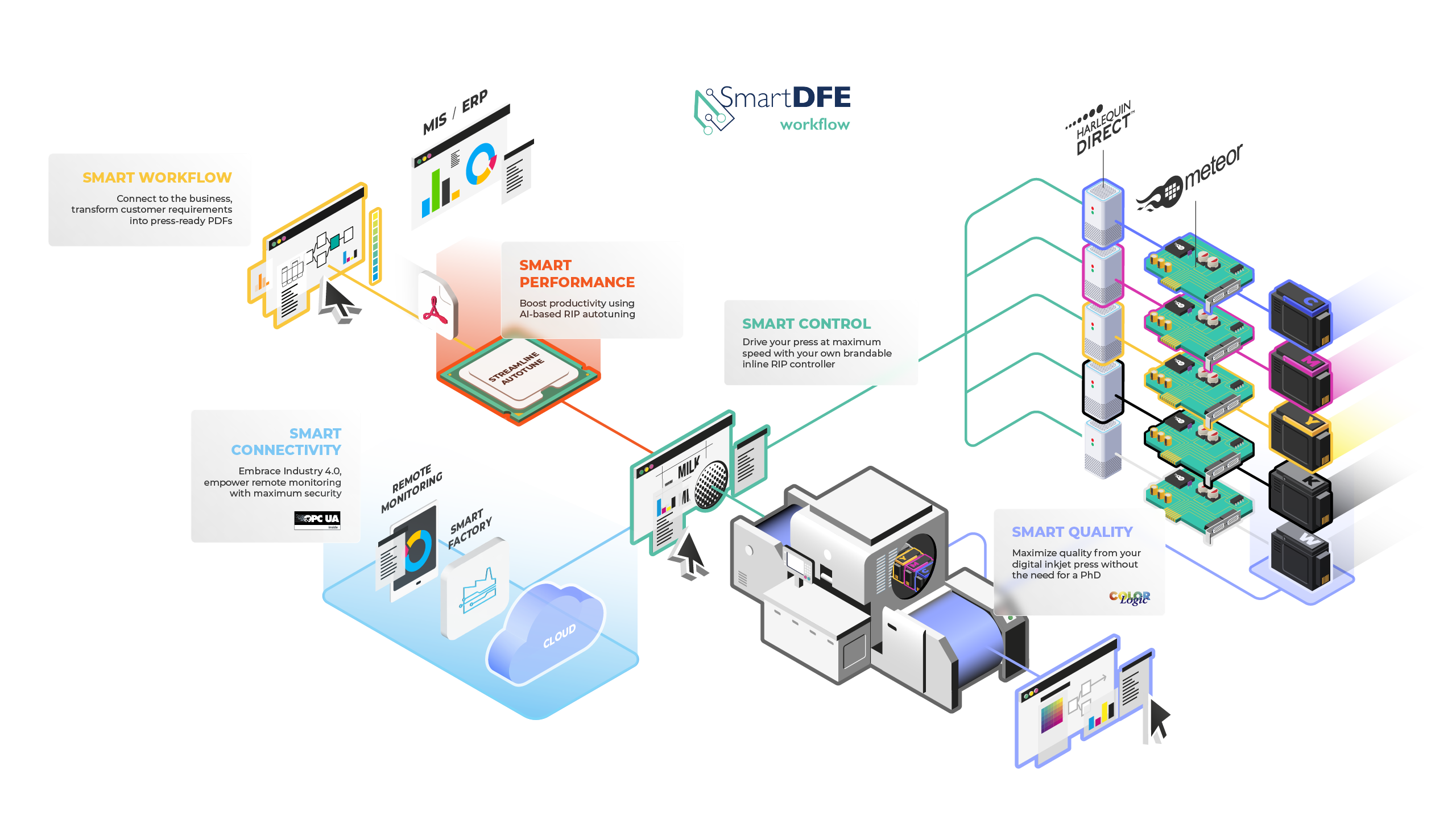

SmartDFE™ is an award-winning collection of innovative and market-proven components that enable your engineering team to get to market quickly whilst giving them the space and capability to add their own value. SmartDFE is a full software stack for high-speed, single-pass, label and packaging inkjet presses. It includes everything from job creation and pre-press workflow through to printhead drive electronics. SmartDFE includes print intelligence, giving you industry-leading quality without the PhD and secure connectivity to power Industry 4.0 scenarios.

Smart Workflow

Smart Workflow is a complete solution designed to optimize and automate labels and packaging production, increasing the productivity of your inkjet press. It brings together two powerful tools:

MIS Link

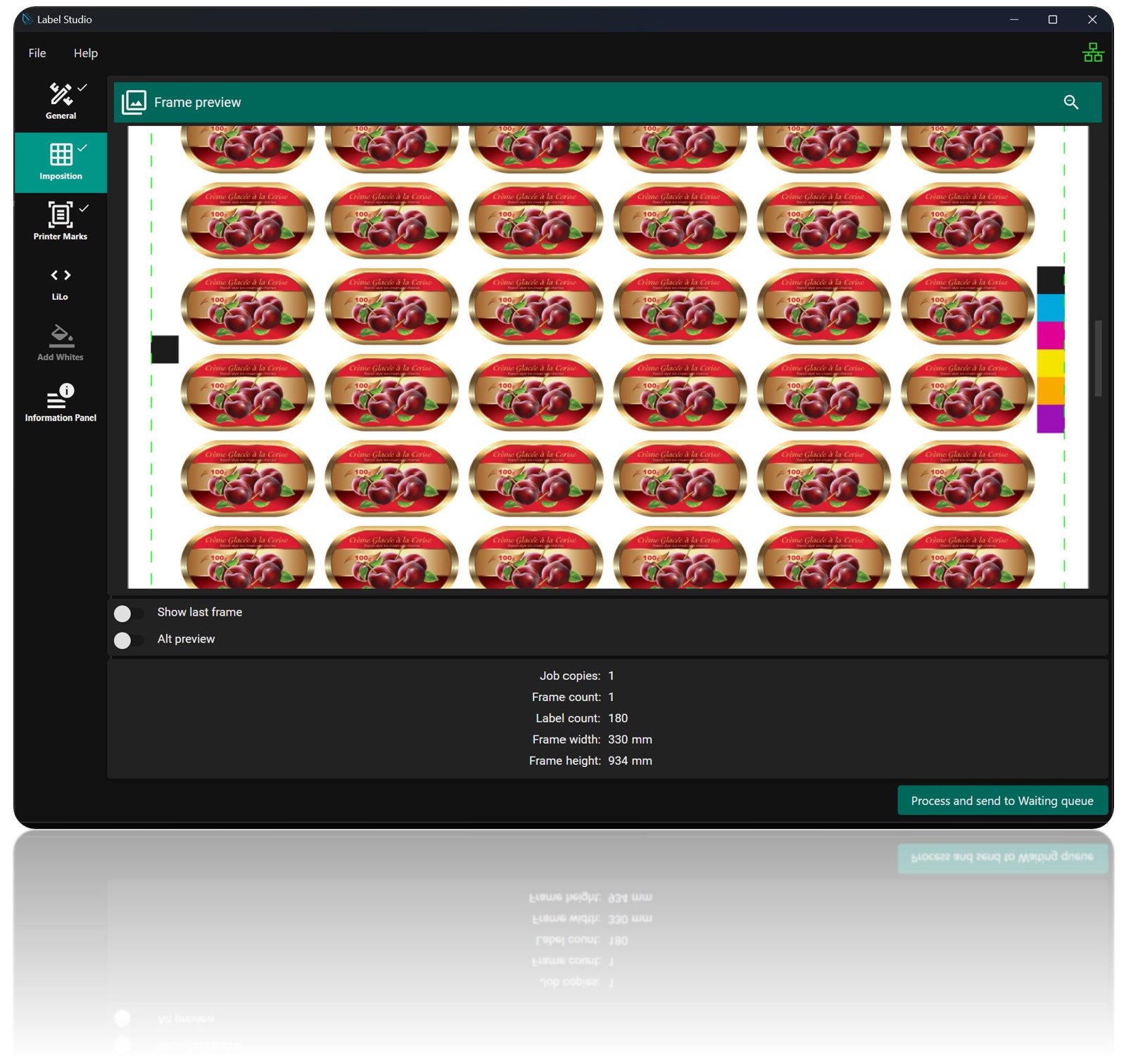

Built on HYBRID Software’s CLOUDFLOW®, MIS Link enables seamless connection to MIS and ERP systems. It also provides a foundation CLOUDFLOW installation that can be expanded as your business needs grow.Label Studio

Integrated within Smart Print Controller, Label Studio gives label press operators the flexibility to prepare jobs directly at the press—ideal when access to the prepress department isn’t available.

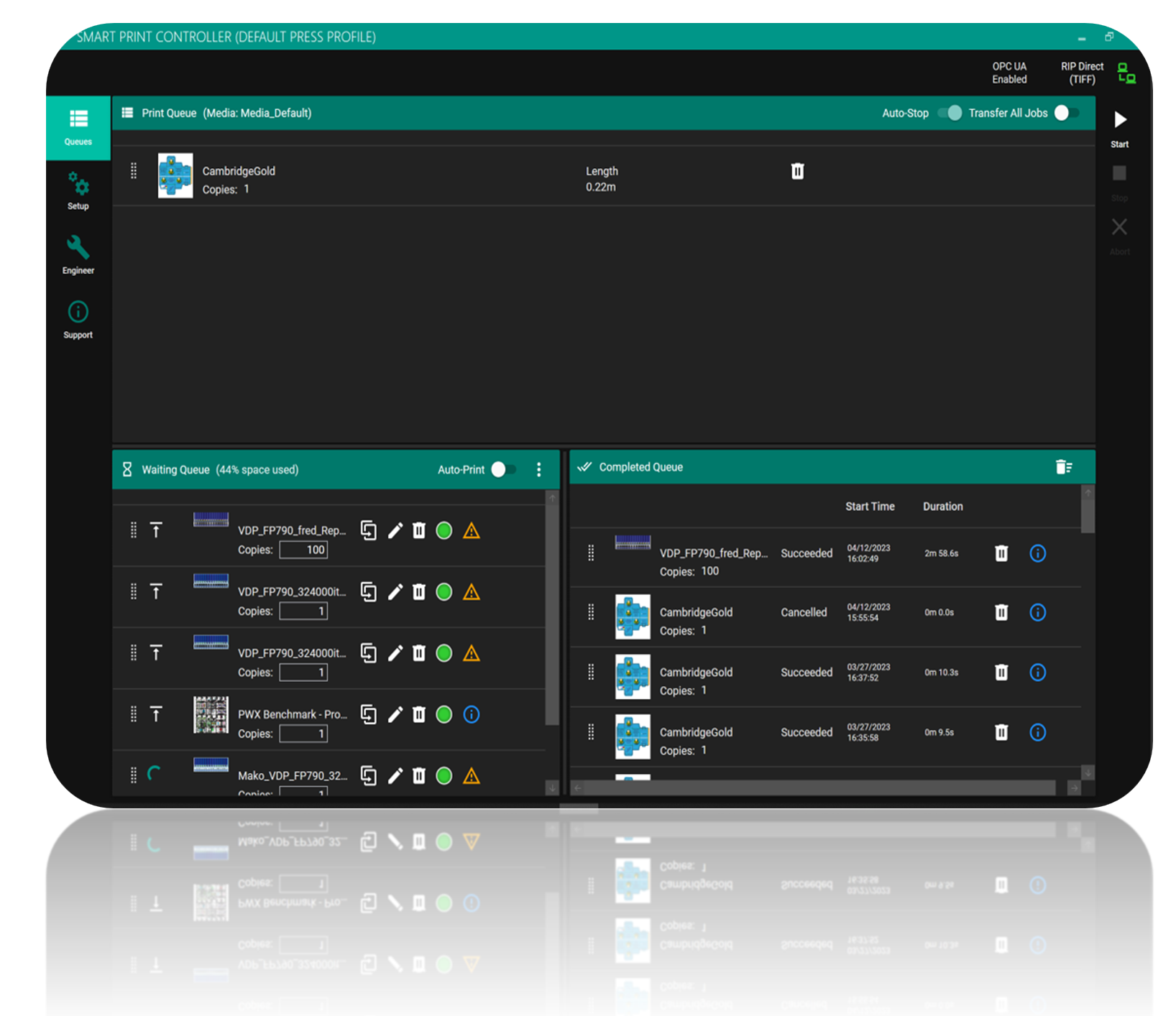

Smart Print Controller

Experience the power of a fully customizable Digital Front End (DFE) that adapts to your brand requirements. This solution provides a seamless entry into the market, enabling swift integration. Operating in server (headless) mode, it also effortlessly complements your existing front end setup. Seamlessly integrate with the Smart Print Controller (SPC) through the OPC UA API, enhancing connectivity.

Smart Connectivity

SmartDFE enables secure communication within printing presses, factories, and the Cloud. It enables Original Equipment Manufacturers (OEMs) to quickly market products using standard press controllers or custom front ends that integrate with existing systems. At its core, the Smart Connectivity layer, powered by OPC UA, ensures robust and secure interactions with devices and applications in the press, Cloud and on mobile, supporting features like remote monitoring and predictive maintenance. SmartDFE incorporates print communication standards (JDF and JMF) for enhanced interoperability and efficiency in print production workflows.

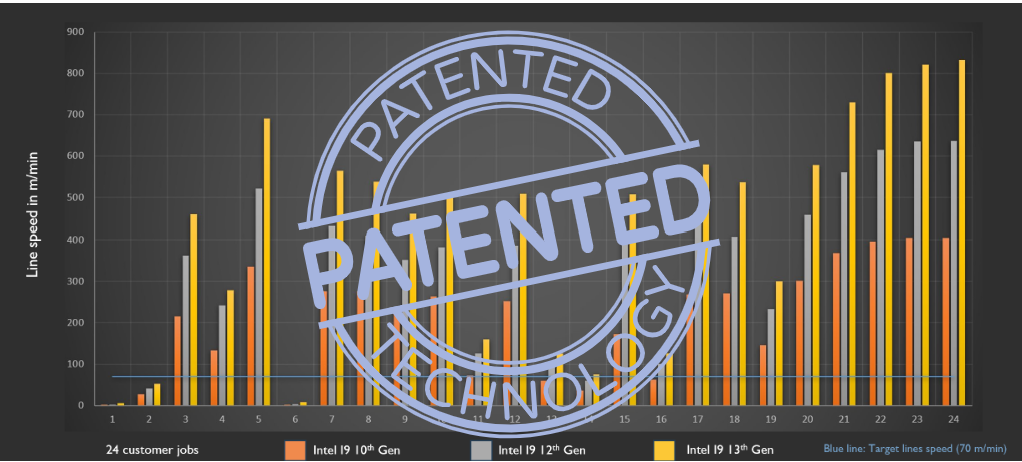

Smart Performance

In the printing industry, even pages that look the same can take different amounts of time to process, which can be a problem. Our Streamline Autotune AI technology helps predict how long a job will take to RIP. It gives operators a clear signal - green means it's safe to print, amber means be cautious, and red means there might be problems. Autotune also enhances performance automatically by adjusting jobs and RIP processes, leveraging our dual ownership of the RIP and PDF analysis technology.

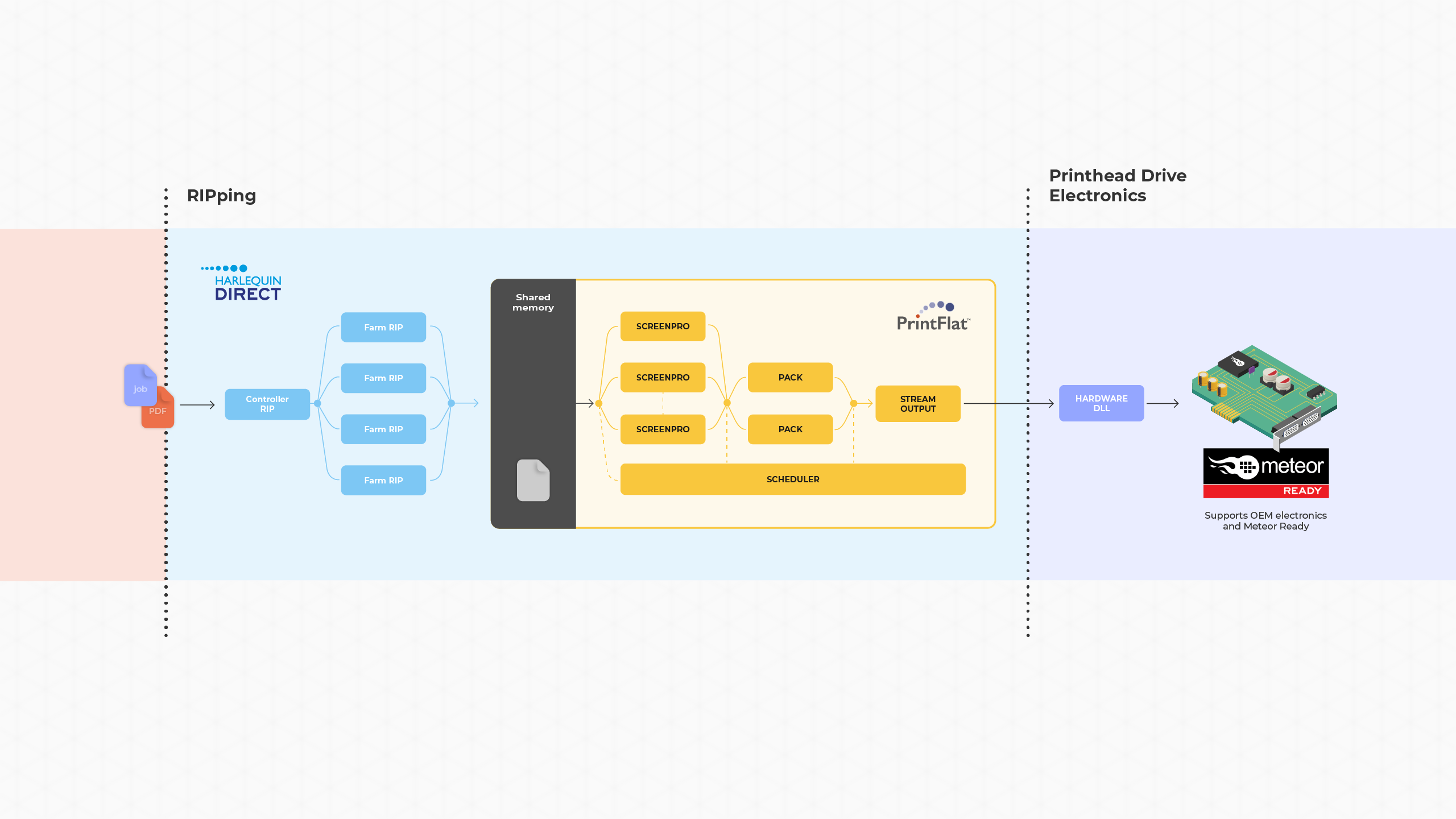

Harlequin Direct

Smart Print Controller is powered by our innovative Harlequin Direct™, which represents a significant advancement in inline RIP technology. It is designed for unprecedented speeds and scalability, marking a new milestone in performance. This solution offers immediate first-page output by directly RIPping PDFs to printhead drive electronics, thus eliminating the need for RIPping ahead. Our distinct edge lies in our independence from third-party core RIP solutions, as we have developed our proprietary Harlequin Core™. This core is widely recognized for its over 30 years of excellence and is acclaimed as the world's fastest RIP core.

Key features of Harlequin Direct:

Uses multi-core and multiple PC configurations for ultra-high-speed and highly scalable RIP processing

Delivers instant first-page output, directly RIPping PDFs to printhead drive electronics, removing the need for preliminary RIPping

Self-reliant with our in-house Harlequin Core, eliminating dependence on external core RIP solutions

Compatible across multiple platforms, including Windows and Linux (Ubuntu and CentOS)

Offers specialized plugins tailored for unique printer functionalities, such as bar splitting and integration with inspection systems

Includes an Output Plugin SDK allowing new output formats and inline functions to be developed

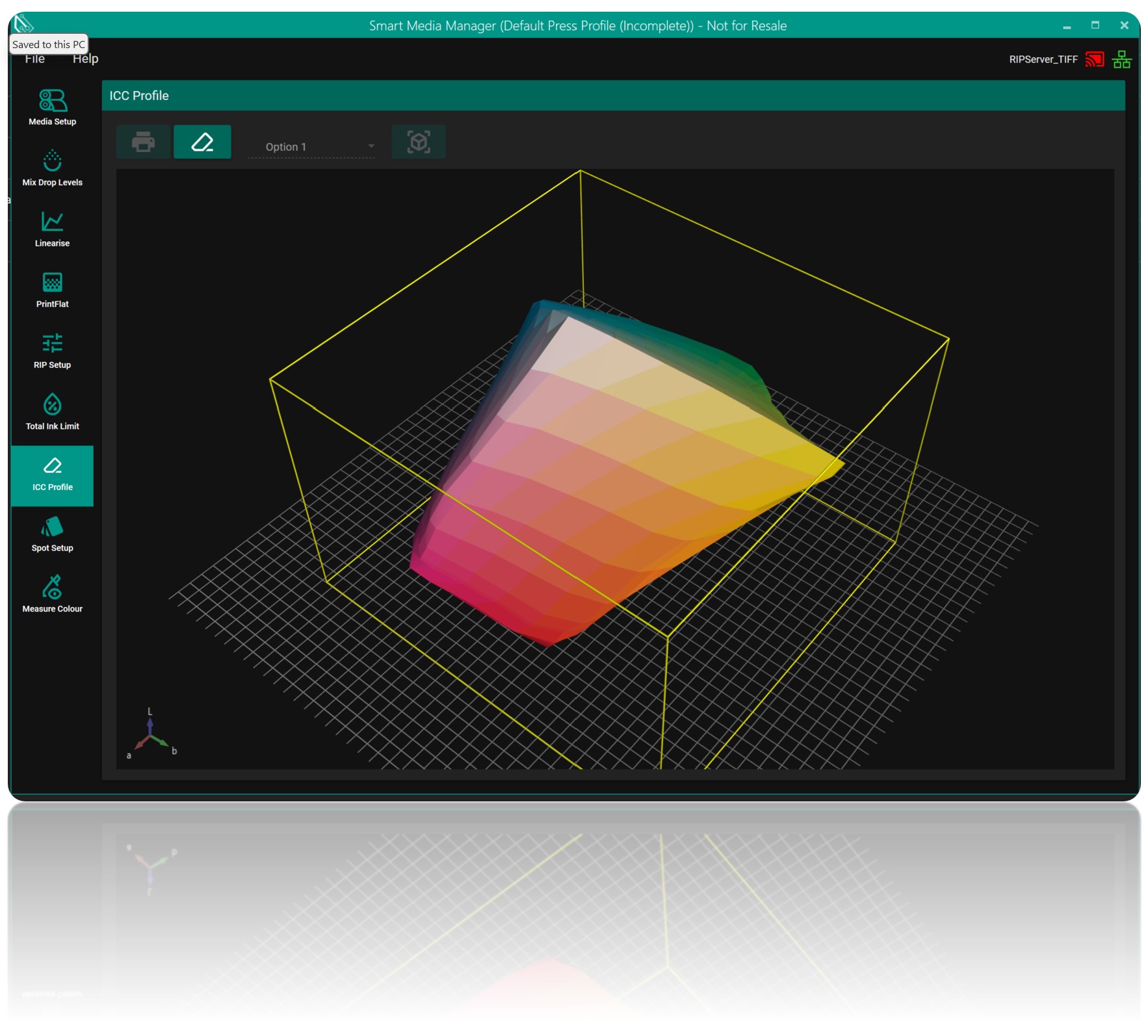

Smart Quality

In today's printing landscape, achieving top-quality prints and precise colors often relies on skilled print operators. However, there's a shortage of these experts. This is especially noticeable in industries integrating print into broader processes, where non-specialists take on printing tasks. To address this, Smart Quality combines advanced technologies like PrintFlat, ScreenPro, and ColorLogic into a user-friendly system, making it easier for any operator to achieve excellent print quality.

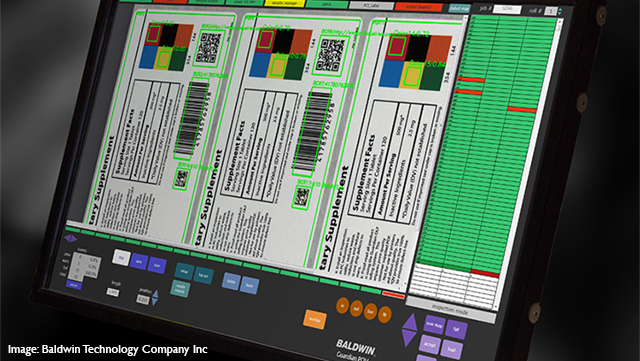

SmartQI

Incorporating an additional RIP Server PC into your system establishes a direct link with a vision system for quality assessment using SmartQI™. This server is adept at delivering RGB composite images to your inspection system, ensuring they are in sync with the rasters sent to the press. Such synchronization is crucial for uniform control of both the printing and inspection processes.

Meteor Inkjet Printhead Drive Electronics

SmartDFE is already compatible with printhead drive electronics from Meteor Inkjet, known for its wide support in industrial inkjet printing. This allows easy integration of different printheads, even from various manufacturers, in one press. Additionally, Meteor Inkjet offers comprehensive tools and services to ensure high product performance and efficient workflows.